The multiple industry segments of manufacturing, along with aerospace, automotive, and historic restoration, rely fundamentally on industrial surface preparation methods. Traditional cleaning approaches, such as sandblasting and manual scrubbing, along with chemical treatments, continue to be standard practices despite creating multiple difficulties that involve environmental hazards, surface deterioration, and expensive operational costs.

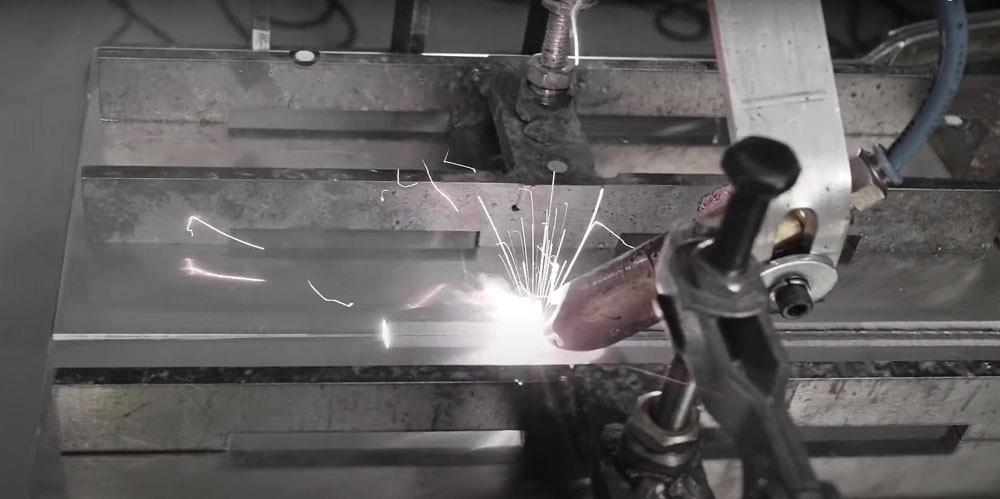

The laser cleaning approach serves as a surface preparation method that utilizes no physical contact and produces neither abrasive nor damaging effects on the environment. A concentrated laser beam guides through this process while it interacts with the material surface. Due to its fine precision, laser cleaning operates as a speedy and precise technology that serves industries requiring precise work with minimal surface deterioration.

The Canadian market is experiencing a transformation through Laser Cleaning methods, which drive surface preparation improvements. The Canadian industrial sectors are quickly implementing laser cleaning technologies because they outperform standard cleaning techniques. Surface preparation is revolutionizing through this technology across Canada as follows:

- Eco-Friendly and Regulatory Compliance

The Canadian industrial sector now places significant emphasis on selecting environmentally responsible sustainable technological solutions. Industrial cleaning methods based on chemicals along with abrasive materials produce dangerous waste products. Laser cleaning manufacturing operations generate zero chemical waste that supports Canadian environmental compliance requirements.

- Cost-Effective with Reduced Downtime

Maintenance activities together with cleaning operations stand as major disruptions which businesses struggle to manage. Business operations using traditional cleaning methods need extended setup periods along with extensive cleaning operations and additional expenses for labor. Laser cleaning services Canada function as an instantaneous dry procedure which removes operational problems. The process enables uninterrupted manufacturing along with maintenance tasks so businesses operate without stopping production to save resources.

- Precision Cleaning for High-Tech Industries

The aerospace sector together with electronics manufacturing and automotive production depend on exact and controlled cleaning processes to achieve their work. Laser cleaning functions as a precise method which enables the elimination of contaminants by safeguarding delicate surfaces. Rigorous quality control standards in various sectors find laser cleaning technologies exceptionally helpful due to their ability to maintain precision while meeting industrial requirements.

- Extends Equipment Lifespan

Equipment maintenance costs and replacement expenses increase because abrasive cleaning practices such as sandblasting remove layer materials from machine components. Because laser cleaning methods use no abrasion they protect industrial equipment from damage that would otherwise shorten its useful life thus saving businesses money on repair or replacement costs.

- Enhances Worker Safety

Clothing workers experience higher health risks because traditional cleaning processes expose them to toxic substances as well as airborne particles and rough abrasive elements. Laser cleaning methods remove the dangerous substances while minimizing airborne hazards thus businesses can achieve safer work conditions and meet workplace safety requirements.

Through laser cleaning solutions Canadian industries are achieving their goal of developing efficient and environmentally sustainable cleaning methods. Organizations that want better productivity at reduced expense together with decreased environmental impact should consider laser cleaning technology as a future-oriented investment. This groundbreaking technology continues to spread throughout Canadian industry which will define the upcoming years of industrial maintenance and manufacturing practices in the country.