Home HVAC (Heating, Ventilation, and Air Conditioning) systems are critical for ensuring comfort and air quality in residential spaces. These systems are responsible for heating and cooling the indoor environment, as well as providing fresh air circulation.

Over time, the metal components of these systems, such as ductwork and other structural elements, may need repairs or upgrades to maintain efficiency and effectiveness. This is where metal welding service comes into play.

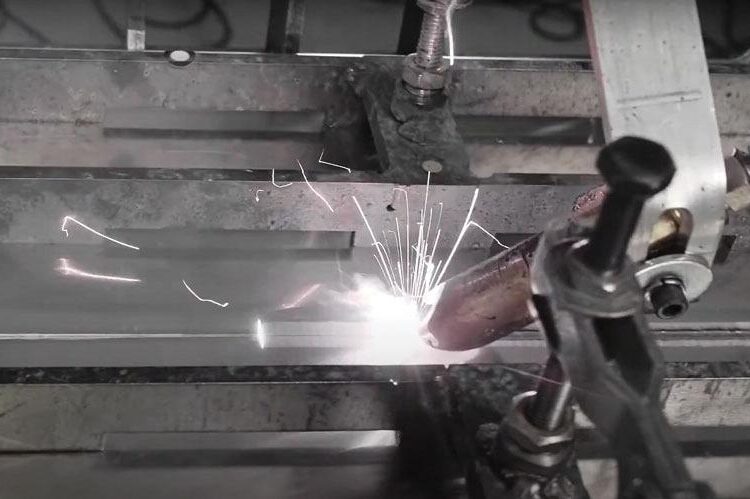

Welding plays a vital role in the installation, maintenance, and repair of various metal parts in HVAC systems. Whether you’re building a new system, upgrading an existing one, or addressing issues with your ductwork, welding provides the necessary strength and durability to ensure that HVAC systems operate smoothly.

Key Welding Applications in HVAC Systems

1. Ductwork Fabrication and Repair

Ducts are the pathways that deliver heated or cooled air throughout a home. They are often made through a process called sheet metal fabrication, including galvanized steel or aluminum, and require precise welding to form strong and leak-free joints. Whether you’re installing new ductwork or repairing existing systems, welding services ensure that the ducts are properly sealed and structurally sound.

Ductwork repairs might include fixing holes, cracks, or loose joints. If any sections of the ducts are damaged due to wear and tear or improper installation, welding can restore the integrity of the system, ensuring proper airflow and preventing energy loss due to leaks.

2. HVAC Units and Metal Frameworks

HVAC units themselves often contain metal components such as support frames, heat exchangers, and condenser coils. These elements may require welding during the manufacturing process or during installation and maintenance. Welding is used to join and strengthen these metal parts, ensuring that the units are durable, stable, and able to withstand the mechanical stresses that come with regular operation.

3. Furnace Repair and Replacement

Furnaces, an essential part of many HVAC systems, rely on metal components like burners, heat exchangers, and venting pipes. Over time, these parts can corrode or degrade, leading to potential breakdowns or safety hazards. Welding services can be used to repair or replace faulty metal components in a furnace, preventing costly replacements and ensuring the system continues to function safely and efficiently.

4. Ventilation Systems

Proper ventilation is essential for maintaining healthy indoor air quality. Metal ducts and venting systems are often subject to high temperatures, moisture, and wear, leading to the need for regular maintenance. Welding is used to seal joints, repair leaks, and ensure that the ventilation system is safe and airtight, which helps prevent the buildup of harmful gases such as carbon monoxide.

5. Custom HVAC Installations

Some homes or buildings require custom HVAC systems that are tailored to unique design specifications or special needs. Welding allows HVAC professionals to create custom metal parts that fit perfectly into the system, ensuring maximum efficiency. Whether it’s a custom air handler or a specialized exhaust vent, welding provides the flexibility to create components that are both functional and durable.

Why Welding is Essential for HVAC Systems

Strength and Durability: Welding ensures that HVAC components are joined together securely and are resistant to wear and tear. This is especially important for systems that undergo constant stress or heat exposure.

- Leak Prevention: Air leaks in HVAC systems can lead to energy inefficiency and higher utility bills. Welding provides a leak-free seal for ducts, pipes, and other metal components, helping to maintain the efficiency of the system.

- Cost Efficiency: Regular maintenance and timely repairs using welding services can extend the life of your HVAC system, preventing the need for expensive replacements.

- Safety: Welding ensures that all joints and seams in the HVAC system are properly sealed, preventing issues such as gas leaks, fire hazards, or carbon monoxide poisoning.

Choosing the Right Welding Services for HVAC Systems

When selecting a welding service for your HVAC system, it’s essential to choose a company with experience working on HVAC components. The metal parts used in HVAC systems require specific welding techniques to ensure proper strength, durability, and safety. A professional welder should be familiar with the types of materials commonly used in HVAC systems, including galvanized steel, aluminum, stainless steel, and copper.

Additionally, it’s important to choose a welding service that adheres to industry standards and safety regulations to ensure that your HVAC system remains in compliance with local building codes.

Conclusion

Welding is an integral part of both the installation and maintenance of home HVAC systems. From fabricating custom ductwork to repairing furnace components, skilled welding services provide the strength and durability needed for an efficient, long-lasting HVAC system.

By ensuring that metal components are properly sealed, secure, and leak-free, welding helps maintain the safety, functionality, and energy efficiency of your HVAC system for years to come.