Does your mechanical design need to incorporate a part that can do some serious heavy lifting? That’s where a hydraulic rotary actuator comes in.

The words ‘hydraulic rotary actuator’ can seem daunting. However, you should know what it is to take advantage of the power it can provide your machines.

Once you break the words down into individual components, the idea is relatively simple.

Read on to find out what these parts are and how they function.

A Break Down of the Hydraulic Rotary Actuator

We can split the concept into three and revisit each part.

What does it mean for a part to be hydraulic as opposed to pneumatic? This simply means that the part uses fluid instead of gaseous compounds to create pressure.

The hydraulic rotary actuator employs an incompressible fluid to create pressure. We redirect that pressure to perform some desired motion under a controlled circumstance.

The fluid used is usually some form of oil, because oil is very hard to compress, thus allowing a lot more energy to be transferred per unit of volume.

Next, what is a rotary part? This refers to the type of motion. In a rotary actuator, motion in one direction (linear motion) gives rise to a rotation.

This allows the rotary actuator to produce torque. Torque measures the rotational force of a part. This is essentially how much power you have available.

Lastly, what is an actuator?

We can compare the actuator’s function in the whole machine to what your muscles do in the body: they enable the conversion of energy to some controlled movement.

So how does the hydraulic rotary actuator function? What is its role in the machine? Let’s put it all together.

In Sum

Hydraulic rotary actuators are able to produce a lot of torque because they convert the energy from the hydraulic pressure into rotational force. They are optimally used in any heavy-duty machinery to enable the performance of some preprogrammed action.

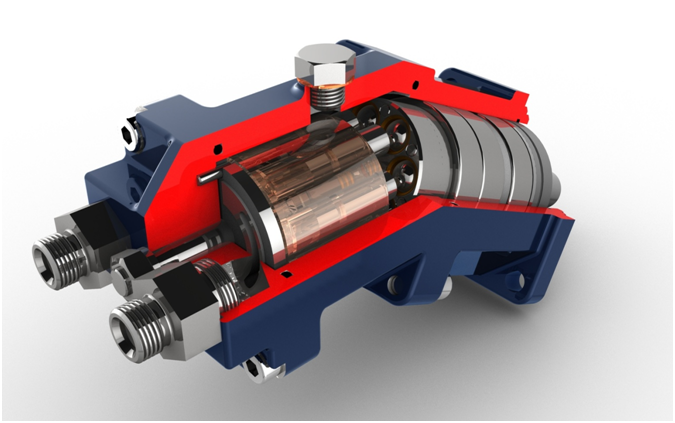

In terms of their structure, they often employ helical splines around a shaft that engage splines on the piston. Engaging the splines and the piston with hydraulic pressure causes the shaft to rotate.

Usage

Do you need to lift heavy items? Turn large components of machinery? Bend stiff materials? Any heavy-duty operation could benefit.

The hydraulic linear actuator, hydraulic valve actuator, or any form of the hydraulic actuator is ideal for these motions. Their simplified design provides a lot of force for what is comparably little volume and weight.

You can invest in actuators that are automated with a service like anythingflows.com, or you can manually control the actuator.

Why Use One

You should employ a hydraulic rotary actuator if you are looking for a mechanical part that can harness and enable a lot of power. They are faster and more efficient than pneumatic actuators in terms of how much torque they can produce.

They are also efficient; using one can save you the space of bulkier components for less force produced per volume unit.

Check out more about construction in our home section!