Ironworkers are the backbone of construction sites, creating the steel framework that supports skyscrapers, bridges, and more. But what exactly does an ironworker do on a daily basis? From the tools they rely on to the techniques they master, ironworkers play a pivotal role in shaping the skeletal structures of buildings, bridges, and more. Let’s walk through a typical day, dive into the essential ironworker tools, and explore the techniques and safety practices that keep these professionals safe and efficient.

The Essential Tools of an Ironworker

One of the first things you’ll notice about an ironworker is the heavy-duty gear they carry. These tools are not just accessories but vital components that help them accomplish tasks like cutting, welding, and bolting metal structures together.

- Iron Worker Tools: Every ironworker’s tool kit contains essentials like wrenches, pliers, hammers, and spud wrenches, specifically designed for working with steel beams and bolts. But it doesn’t stop there; they also rely on specialized tools like bull pins to align holes in steel beams, and sleever bars for tightening bolts.

- Ironworker Tool Belt: Since ironworkers often find themselves high above the ground, having their tools readily accessible is crucial. This is where the ironworker tool belt comes into play. This sturdy belt holds all the necessary tools securely, allowing workers to move swiftly without having to worry about reaching down for the right tool.

- Ironworker Boots: When it comes to footwear, ironworker boots aren’t just about comfort; they’re a lifeline. These boots are specifically designed with steel toes and a wedge sole for added grip, providing stability on the often slippery steel beams.

- Ironworker Hard Hat: Working in hazardous conditions, an ironworker must always protect their head. The ironworker hard hat is a vital part of their safety gear, protecting them from falling debris or accidental head bumps against sharp objects.

Techniques That Define Ironwork

Working on massive steel structures isn’t as simple as swinging a hammer or tightening a bolt. Ironworkers employ various techniques to get the job done quickly and accurately.

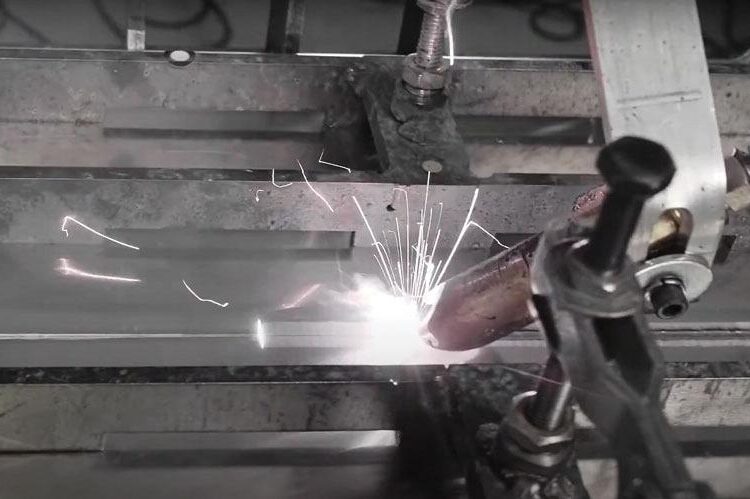

One of the most vital skills in ironworking is welding. Ironworkers often weld beams together, ensuring the structure’s integrity. Another essential technique is bolting, where large steel bolts are tightened to hold beams in place. Often working at great heights, ironworkers must ensure each bolt is perfectly aligned, relying heavily on their spud wrenches and bull pins.

Precision is everything. When erecting a skyscraper or a bridge, there’s no room for mistakes. Each beam, bolt, and weld must be perfectly placed, as even a slight misalignment can compromise the entire structure. Ironworkers work closely with engineers to ensure everything is in place, and often the job involves making on-the-spot adjustments to ensure that steel beams fit together like puzzle pieces.

Safety First: Ironworker Safety Practices

The dangers that ironworkers face daily are immense, but safety is always their top priority. From the right safety equipment to constant awareness of their surroundings, ironworkers follow strict safety protocols to minimize risks. Let’s break down some of their most critical safety practices.

- Proper Ironworker Tools: Using the right tools for the job isn’t just a matter of efficiency; it’s also about safety. Each tool in an ironworker’s arsenal is designed to handle heavy loads and withstand extreme conditions. Without the proper ironworker tools, the risk of injury increases significantly. Properly maintained tools also reduce the risk of accidents.

- Ironworker Hard Hat: A safety essential, the ironworker hard hat protects workers from falling debris, overhead hazards, and accidental impacts.

- Climbing Belt and Harnesses: Safety equipment like the lineman climbing belt and full-body harnesses are critical for keeping ironworkers secure when working at great heights. No ironworker would dare step onto a steel beam hundreds of feet above the ground without being properly strapped in.

- Shotgun Stick: For those ironworkers dealing with electrical components, the shotgun stick is indispensable. This tool allows workers to safely manipulate live wires from a distance, ensuring that they aren’t exposed to dangerous high-voltage currents.

- Boots Designed for Stability: Another crucial safety element is the ironworker boots. These boots offer the kind of stability and grip necessary to walk along narrow, slippery steel beams without slipping or losing balance.

Techniques to Ensure Safety in Hazardous Environments

Safety on the job requires both the right gear and the right techniques. Ironworkers are trained to stay hyper-aware of their surroundings, whether working on the ground or high up in the air. They always maintain three points of contact when climbing steel structures, ensuring they have a firm grip before making a move.

Additionally, they work in teams, always communicating and looking out for one another. Ironworkers are often responsible not only for their own safety but also for that of their coworkers. Many times, a simple shout of “heads up!” can prevent an injury when debris or tools fall from above.

Safety drills and regular inspections of equipment are also vital. Ironworkers make it a point to inspect their gear, including their tool belts, boots, and hard hats, before each shift. Small things like a loose bolt or a worn-out strap could lead to significant accidents if not caught early.

Conclusion: A Day Full of Challenges and Rewards

Ironworking isn’t for the faint of heart. It requires skill, precision, and an unwavering commitment to safety. From selecting the right tools, like the ironworker tool belt and ironworker boots, to employing critical techniques like welding and bolting steel beams together, every task demands focus and expertise. The safety practices ironworkers follow, including wearing the right gear and staying aware of their surroundings, ensure they can tackle these immense challenges while staying safe.

Next time you see a towering skyscraper or cross a sturdy bridge, remember the ironworkers who helped build it. Their tools, techniques, and safety practices are what make these feats of engineering possible.

FAQs

- What are the most important tools for an ironworker?

Ironworkers rely on various tools like spud wrenches, bull pins, sleever bars, and welding gear, all of which are stored in their ironworker tool belt. - What safety equipment do ironworkers use when working at heights?

Ironworkers use a combination of hard hats, lineman climbing belts, full-body harnesses, and ironworker boots to ensure safety while working high above the ground. - Why are ironworker boots different from regular work boots?

Ironworker boots are designed for grip and stability, featuring steel toes and wedge soles, allowing workers to safely navigate narrow, slippery steel beams. - How do ironworkers stay safe when working with electricity?

Ironworkers handling electrical tasks use tools like the shotgun stick to manipulate live wires from a safe distance, along with proper personal protective equipment. - What is the purpose of the ironworker hard hat?

The ironworker hard hat protects workers from falling objects, debris, and accidental bumps in dangerous construction environments.